Readiness Certification Assurance (RCA) Process

The Backstory of the Readiness Certification Assurance Process

So what is this RCA Process?

The Department of Energy (DOE) regulates high-risk activities under its jurisdiction via a series of directives. One of those directives (DOE Order 425.1, Verification of Readiness to Start up or Restart Nuclear Facilities) requires that verification reviews be conducted on new or restarted facilities or processes to verify the readiness of that facility or process to safely and compliantly operate. Prior to starting this verification review, the contractor’s management responsible for operating the facility or process must:

- Issue a formal written memorandum certifying that the facility or process is ready for startup or restart;

- Verify that the preparations for startup or restart have been completed; and

- Verify that any prerequisites for safe and compliant operations have been met.

Definitions:

“Certify” management has officially attested or authoritatively confirmed as complying with specified requirements or standards.

“Verify” management has substantiated or confirmed, with evidence, that specific requirements are met.

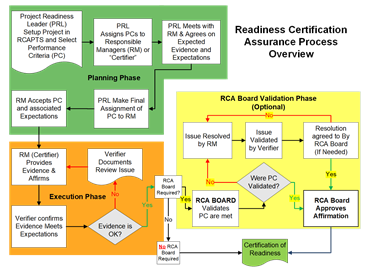

The RCA process is a means to establish or specify the set of requirements or standards that the facility or process must meet and provide the structure to verify the requirements have been met and to capture electronically the evidence of that verification.

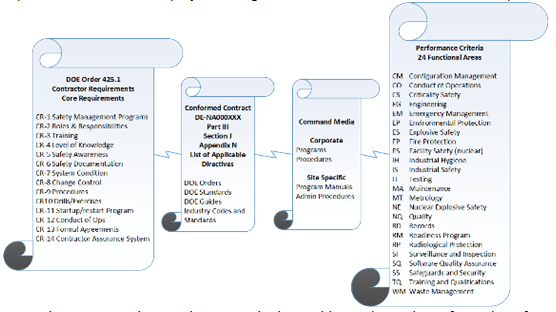

In the case of most highly regulated industries the set of defined requirements are those established by the regulatory agency or in the case of DOE, they are established by the contract between the managing contractor and DOE. Contract requirements are typically implemented through site command media (i.e., procedures) applicable to the scope of the Startup or restart. Other regulatory bodies might issue guides or standards containing the requirements to gain their approval.

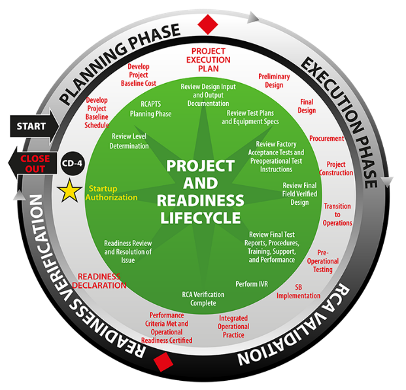

Early identification of the requirements that must be met, and in process (i.e., integrated with the project management lifecycle) verification that they are met, are key elements for successfully achieving operational readiness.

Management certification of operational readiness means they have completed a defined and documented process that provides a high level of confidence that should the verification review not be performed, then they could immediately (with no further actions needed) begin the work processes required in a safe and compliant manner that will ensure mission objectives are met.

The Readiness Certification Assurance process is designed to accomplish this systematic approach to verifying that a set of defined requirements applicable to a specific scope of work have been met and quality evidence exists to demonstrate that fact regardless of whether or not the regulatory body will validate the achievement.

Readiness Certification Assurance

Capturing the set of Requirements

In the case of sites regulated by DOE, the Core Requirements from DOE O 425.1 were evaluated against the site specific DOE contract to identify applicable directives, and determine how the requirements from those directives flow into corporate or site Command Media (i.e., procedures). The applicable Command Media define the expected documents (i.e., evidence) and records that would demonstrate compliance.

From the Command Media, Performance Criteria are developed to establish the detailed expectations needed to assure upper level requirements are met. The Performance Criteria each capture the associated source documents (procedures) that contain the requirements along with the expected evidence (documentation) that the Command Media requires to be produced, including the expectations for the content and quality of that documentation.

The performance criteria can also be associated with the specific regulatory requirements contained in agency guides or industry standards. In addition, the evidence for each performance criterion can be binned according to type of document (e.g., Purchase Request, Work Instruction, operating procedure, Maintenance Work Order, etc.), to allow for sorting when the evidence is displayed for a review.

Integration with Project

The Integrated RCA Process